How to Choose the Right Carbon Steel Flange for Your Project: A Comprehensive Guide

2025-10-01

How to Choose the Right Carbon Steel Flange for Your Project

Table of Contents

- 1. Introduction to Carbon Steel Flanges

- 2. Types of Carbon Steel Flanges

- 3. Key Specifications of Carbon Steel Flanges

- 4. Understanding Material Grades

- 5. Dimensions and Pressure Ratings

- 6. Proper Installation Techniques

- 7. Maintenance Tips for Longevity

- 8. Common Mistakes to Avoid

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Carbon Steel Flanges

Carbon steel flanges play a crucial role in various industrial applications, acting as connectors between pipes, valves, and other equipment. These flanges are designed to withstand high pressure and temperature, making them ideal for a range of projects, from plumbing systems to complex industrial setups. Understanding how to choose the right carbon steel flange is essential for ensuring the integrity and efficiency of your project.

2. Types of Carbon Steel Flanges

When selecting carbon steel flanges, it is important to familiarize yourself with the different types available:

2.1 Weld Neck Flanges

Weld neck flanges feature a long tapered neck that provides excellent strength and resistance to stress. These are ideal for high-pressure applications.

2.2 Slip-On Flanges

Slip-on flanges are easy to install and are often used in low-pressure systems. They slide over the pipe and are welded in place.

2.3 Blind Flanges

Blind flanges are solid with no hole, used to close off a piping system. They are perfect for isolating sections of a pipeline.

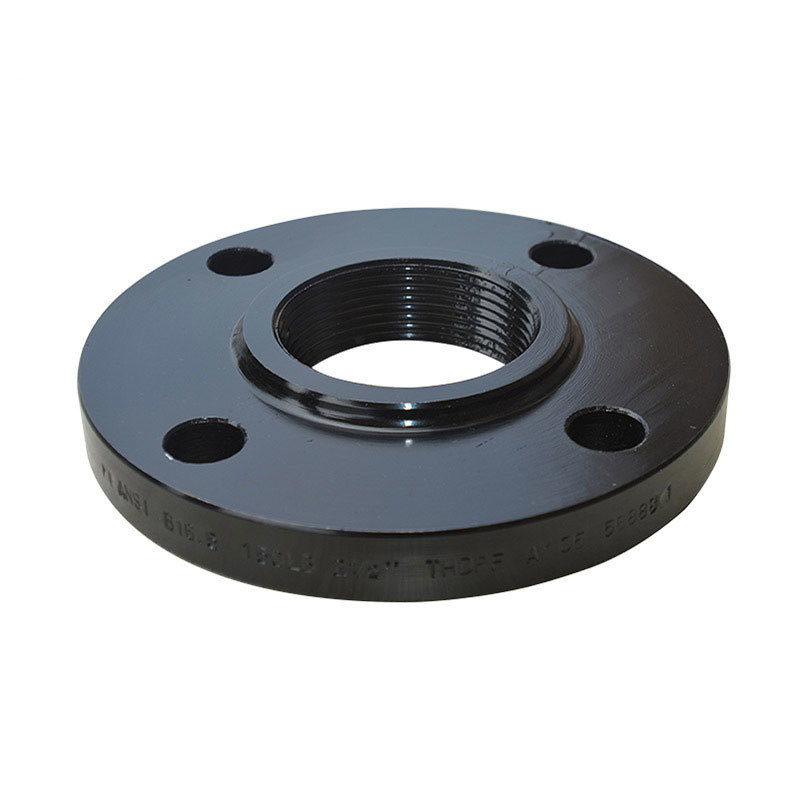

2.4 Threaded Flanges

Threaded flanges have internal threads that allow them to be screwed onto the pipe. They are suitable for applications where welding is impractical.

3. Key Specifications of Carbon Steel Flanges

Understanding the specifications of carbon steel flanges is essential for making the right choice. Key specifications include:

3.1 Flange Thickness

Flange thickness varies based on type and size. Thicker flanges can withstand greater pressure and are essential for high-stress applications.

3.2 Bolt Hole Patterns

Bolt hole patterns must match the corresponding pipe connections. Ensure compatibility to avoid installation issues.

3.3 Surface Finish

The surface finish of a flange can affect its performance. Smooth finishes reduce friction and improve sealing, while rough finishes may provide a better grip for gaskets.

4. Understanding Material Grades

Carbon steel flanges come in various material grades, each suited for specific applications:

4.1 A105

A105 flanges are commonly used for carbon steel flanges in piping systems that operate at room temperature and above.

4.2 A350 LF2

These flanges are ideal for low-temperature applications, ensuring performance in harsh environments.

4.3 A182 F304

A182 F304 flanges are used in corrosive environments, offering excellent resistance to oxidation and corrosion.

5. Dimensions and Pressure Ratings

Choosing the right dimensions and pressure ratings is vital for optimal performance:

5.1 Pipe Size Compatibility

Select flanges that match the pipe size to ensure a proper fit and seal.

5.2 Pressure Rating Classes

Flanges come in various pressure ratings, such as 150, 300, and 600. It's crucial to select a flange with a rating that exceeds the operational pressure of your system.

6. Proper Installation Techniques

Proper installation of carbon steel flanges ensures longevity and reliability:

6.1 Prepare the Surface

Clean the flange and pipe surfaces to remove debris and rust, ensuring a proper seal.

6.2 Use Appropriate Gaskets

Select gaskets compatible with both the flange material and the operating conditions to prevent leaks.

6.3 Tightening Bolts

Follow a star pattern when tightening bolts to ensure even pressure distribution. Over-tightening can lead to deformation, while under-tightening may cause leaks.

7. Maintenance Tips for Longevity

Regular maintenance can prolong the life of carbon steel flanges:

7.1 Routine Inspections

Conduct regular inspections for signs of wear, corrosion, or leaks to address issues early.

7.2 Lubrication

Apply a suitable lubricant to bolt threads to prevent seizing, making future maintenance easier.

7.3 Cleaning

Keep flanges clean from corrosion-causing contaminants, ensuring optimal performance.

8. Common Mistakes to Avoid

Avoiding common pitfalls can enhance the success of your project:

8.1 Not Considering Application Needs

Always consider the specific needs of your application, including pressure, temperature, and environmental factors.

8.2 Ignoring Manufacturer Guidelines

Follow manufacturer guidelines for installation and maintenance to ensure optimal performance and warranty coverage.

8.3 Selecting Incompatible Flanges

Ensure compatibility between flanges, pipes, and other components to avoid leaks and failures.

9. Frequently Asked Questions

9.1 What is the difference between carbon steel and stainless steel flanges?

Carbon steel flanges are typically more cost-effective and offer good strength, while stainless steel flanges provide superior corrosion resistance.

9.2 How do I know which flange type to choose?

Consider factors such as pressure requirements, ease of installation, and the specific needs of your piping system.

9.3 Can carbon steel flanges be reused?

Yes, but they should be thoroughly inspected for damage or wear before reuse.

9.4 What are the common causes of flange failure?

Flange failure can result from improper installation, corrosion, and exceeding pressure or temperature ratings.

9.5 How can I improve the sealing of carbon steel flanges?

Use high-quality gaskets and ensure proper torque when installing the bolts to improve sealing and prevent leaks.

10. Conclusion

Choosing the right carbon steel flange for your project involves understanding the types, specifications, and installation techniques essential for maintaining integrity and functionality. By considering the factors outlined in this guide and avoiding common mistakes, you can enhance the performance and longevity of your piping systems. Whether you're working on a small plumbing project or a large-scale industrial installation, selecting the appropriate flanges will ensure success and reliability in your endeavor.

Previous:

Contact Us

Email:

info@bfflange.com

Phone/WeChat:

+86-15373337981

Address:

China-Hebei Province, Cangzhou City, Yanshan County, South City Puwaicheng Development Zone