The Importance of Weld Neck Flanges in Oil and Gas Applications

2025-10-03

The Importance of Weld Neck Flanges in Oil and Gas Applications

Table of Contents

- 1. Understanding Weld Neck Flanges

- 2. Key Features of Weld Neck Flanges

- 3. Advantages of Using Weld Neck Flanges in Oil and Gas

- 4. Applications of Weld Neck Flanges in the Oil and Gas Industry

- 5. Comparison with Other Types of Flanges

- 6. Installation and Maintenance Best Practices

- 7. Challenges in Using Weld Neck Flanges

- 8. FAQs about Weld Neck Flanges in Oil and Gas

- 9. Conclusion

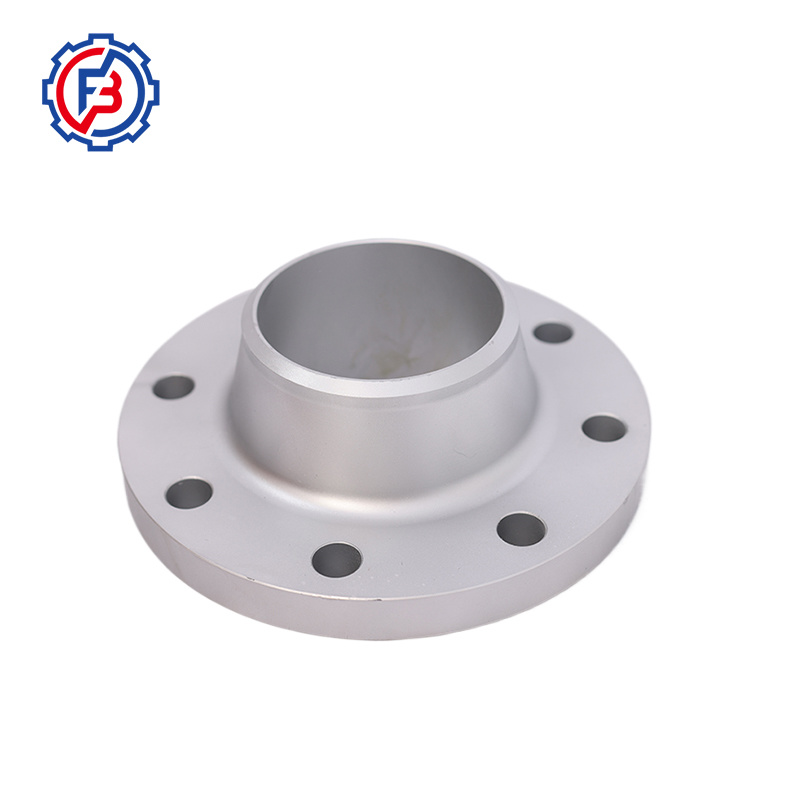

1. Understanding Weld Neck Flanges

Weld neck flanges are integral components used in piping systems, particularly in the oil and gas sector. Characterized by their long tapered neck, these flanges are designed to be welded to the pipe, providing a smooth transition from the pipe to the flange. This unique design minimizes stress concentration at the joint, making them ideal for high-pressure applications. The weld neck flange's geometry helps facilitate the flow of fluids and gases, ensuring operational efficiency and longevity.

2. Key Features of Weld Neck Flanges

Weld neck flanges possess several features that make them effective in oil and gas applications:

2.1 Tapered Neck Design

The tapered neck allows for a gradual transition between the flange and the pipe, which is crucial in minimizing turbulence and maximizing flow efficiency.

2.2 High Strength and Durability

Constructed from materials like carbon steel, stainless steel, and alloy steel, weld neck flanges are built to withstand extreme temperatures and pressures, which are common in oil and gas operations.

2.3 Variety of Sizes and Class Ratings

These flanges are available in various sizes and pressure class ratings, allowing them to be customized for different applications and ensuring compatibility with existing systems.

2.4 Resistance to Corrosion

Many weld neck flanges are coated or made from corrosion-resistant materials, which is essential in environments exposed to harsh chemicals and environmental conditions.

3. Advantages of Using Weld Neck Flanges in Oil and Gas

In the oil and gas industry, the use of weld neck flanges offers several advantages:

3.1 Enhanced Safety and Reliability

Due to their welded connection, weld neck flanges help minimize the risk of leaks and failures, which is critical in maintaining safety in hazardous environments.

3.2 Reduced Maintenance Costs

The durability and strength of weld neck flanges lead to a longer lifespan and reduced need for maintenance compared to other flange types, resulting in lower life-cycle costs.

3.3 Improved Structural Integrity

The design of weld neck flanges helps distribute loads evenly, reducing the likelihood of flange separation and ensuring the overall integrity of the piping system.

3.4 Versatility in High-Pressure Applications

Weld neck flanges are particularly advantageous in applications involving high-pressure gas and fluid transport, where other flange types may fail under stress.

4. Applications of Weld Neck Flanges in the Oil and Gas Industry

Weld neck flanges find use in various applications within the oil and gas sector, including:

4.1 Pipeline Systems

These flanges are commonly used in pipeline systems for transporting crude oil, natural gas, and other fluids over long distances.

4.2 Refineries and Processing Plants

In refineries, weld neck flanges connect different units and equipment, facilitating the processing of hydrocarbons into marketable products.

4.3 Offshore Platforms

Weld neck flanges are vital in offshore drilling and production platforms, where they help ensure robust connections that can withstand harsh marine environments.

4.4 Storage Facilities

In storage tanks and facilities, weld neck flanges play a crucial role in maintaining the structural integrity of the tanks and preventing leaks.

5. Comparison with Other Types of Flanges

When evaluating flange options for oil and gas applications, it's essential to compare weld neck flanges with other types:

5.1 Slip-On Flanges

Unlike weld neck flanges, slip-on flanges are placed over the pipe's end and are less secure under high-pressure conditions. They are more susceptible to leaks.

5.2 Blind Flanges

While blind flanges are used to seal off piping systems, they lack the versatility and strength of weld neck flanges, which are better suited for high-pressure applications.

5.3 Threaded Flanges

Threaded flanges do not require welding, but they are generally not recommended for high-pressure applications due to the risk of failure at the joint.

6. Installation and Maintenance Best Practices

Ensuring proper installation and maintenance of weld neck flanges is vital for maximizing their effectiveness. Here are best practices to consider:

6.1 Proper Alignment

Ensure that the flange and pipe are perfectly aligned before welding. Misalignment can lead to uneven stresses and potential failures.

6.2 Use of Correct Welding Techniques

Utilize appropriate welding methods to ensure a strong bond. Techniques such as TIG (Tungsten Inert Gas) welding are often recommended for high-strength applications.

6.3 Regular Inspections

Conduct periodic inspections to identify any signs of wear, corrosion, or damage. Early detection can prevent catastrophic failures and leaks.

6.4 Maintaining Cleanliness

Keep the area around the flange clean and free from contaminants that could affect the integrity of the weld or the flange itself.

7. Challenges in Using Weld Neck Flanges

Despite their many benefits, there are challenges associated with weld neck flanges that industry professionals should be aware of:

7.1 High Initial Cost

Weld neck flanges can have a higher upfront cost due to their design and manufacturing process. However, this cost is often offset by their durability and lower maintenance needs over time.

7.2 Complexity in Installation

The installation of weld neck flanges requires skilled labor and precise techniques, which can complicate the installation process compared to simpler flange types.

7.3 Limited Availability

Certain sizes or materials of weld neck flanges may be less readily available, leading to potential delays in project timelines.

8. FAQs about Weld Neck Flanges in Oil and Gas

8.1 What materials are weld neck flanges made from?

Weld neck flanges are commonly made from carbon steel, stainless steel, and various alloys, depending on the requirements of the application.

8.2 How do I know if a weld neck flange is suitable for my application?

Consider the operating pressure, temperature, and the type of fluid being transported. Consult with an engineering professional to ensure compatibility.

8.3 Can weld neck flanges be reused?

In some cases, weld neck flanges can be reused if they are inspected and deemed free from damage. However, it’s essential to assess the flange and its welds before reinstallation.

8.4 What is the typical lifespan of a weld neck flange?

The lifespan can vary based on factors such as material, environmental conditions, and maintenance practices, but they are designed to last many years, often 20 years or more in optimal conditions.

8.5 Are there alternatives to weld neck flanges?

Yes, alternatives include slip-on flanges, blind flanges, and threaded flanges, though they may not offer the same advantages in high-pressure situations.

9. Conclusion

Weld neck flanges play a crucial role in the oil and gas industry, promoting safety, efficiency, and reliability in complex piping systems. Their unique design, coupled with the advantages of strength and versatility, makes them an indispensable component in high-pressure and high-temperature applications. By understanding the benefits and challenges of weld neck flanges, industry professionals can make informed decisions, ensuring the integrity of their operations while optimizing performance and minimizing risks. Investing in high-quality weld neck flanges is not merely a functional choice but a strategic decision that bolsters operational safety in the demanding world of oil and gas.

Previous:

Contact Us

Email:

info@bfflange.com

Phone/WeChat:

+86-15373337981

Address:

China-Hebei Province, Cangzhou City, Yanshan County, South City Puwaicheng Development Zone